Replenishment

Table of Contents

Replenishment

Replenishment refers to a process where the quantity of real money in the small money box is brought to match the value shown in the little cash overall ledger category. This occurs at the conclusion of each billing period; and any time there is not enough real money in the small currency box. The required sum is written out on the primary debit card of the business. Cash will benefit from this.

An outside company that the bank has contracted to restock the ATM takes out the old cash and inserts it using a new batch. Depending on their faith, financial notes are placed into tapes. Once the cash packets have been thoroughly examined and evaluated, accuracy will be high.

What is replenishment?

The idea of refilling is related to small-scale funds, which are typically controlled via petty money boxes and stocks. These monies are utilised to cover minor daily costs and activities. Cash is removed from the financial institution’s account and deposited in the containers as the resources deplete with the goal to refill the amount of money. Petty cash containers act as an incentive for upholding tiny activities since cumbersome payment methods can occasionally reduce production.

A restocking order could also be issued by the individual with oversight of managing the small-scale funds of replenishment. Evaluating the expenditures that have been incurred and covered with small amounts of money is the first step in the procedure for replenishing. The small coin box is subsequently refilled with more cash to bring the balance up to the predetermined level. A replenishing procedure has the benefit of ensuring that utilised monies are being accurately audited.

Understanding replenishment

Replenishment refers to the planned and frequent transfer of inventories from a logistics node upstream to one downward that needs enough stock to meet demand. According to the type of firm and the situation, the method of replenishing stock varies. The various types of replenishment are:

- Moving stock from scheduled merchandise storage to wrapping and delivery spots.

- Directing supplies from manufacturers to make certain that a distribution centre or fulfilment centre has enough product.

- Transporting stock from a warehouse to a pick-up facility or retail is an example of the replenishment process.

Importance of replenishment

The preservation of effective demand and line-item fill costs, and replenishment serves to preserve the movement of inventory across the financial value chain. Without a good replenishment strategy, organisations run the danger of losing money.

Refilling stock aids in ensuring that the appropriate quantity of goods is offered for purchase at the appropriate moment. This is service client requests without overstocking or stockouts. This also aims to maintain the price of attaining stock to a minimum as feasible for the business.

Since this involves determining the amount of inventory to keep on hand for every item, the stock replenishing process integrates with demand estimation and logistics factors.

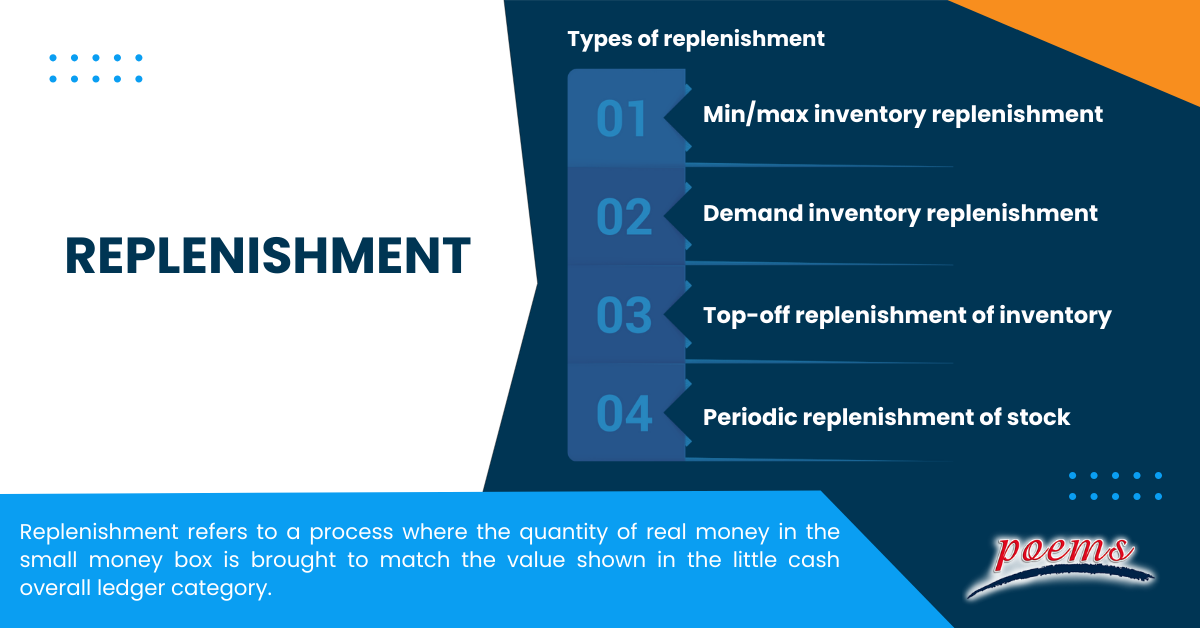

Types of replenishment

Simulations and techniques for replenishing stock assist companies in establishing supplies; placing best practices; managing replenishment rates; monitoring the circulation of goods; calculating the number of things to be purchased; and determining the ideal level of supplies to be kept in storage facilities for supply chain effectiveness. The numerous replenishing methods include:

- Min/max inventory replenishment. – The min/max replenishment method initiates refilling operations when an item reaches a predefined low threshold. The greatest applications for this are SKUs having consistent flow and seasonally anticipated demand.

- Demand inventory replenishment – Need inventory replenishment provides well for facilities with restricted rooms and select locations. It works well in circumstances where it is ineffective to devote a lot of space.

- Top-off replenishment of inventory – The top-off restocking method frequently operates on a set timetable or group releases and employs parameters that are identical to those used in the min/max replenishment approach.

- Periodic replenishment of stock – The quantity of stock required for particular times is transported to select locations in facilities using periodic replenishment models.

Examples of replenishment

Transportation of needed supplies from providers to factories; moving stock from maintained warehouses to wrapping and transport locations; and requesting goods to manufacturers to make certain the warehouse and fulfilment centre has enough goods, are all examples of replenishment.

Frequently Asked Questions

The planned and routine transportation of inventories from an upper side in the supply network to a lower position that needs sufficient supplies to meet the need constitutes the working principle of replenishment.

While preserving effective demand or line-item fulfilment rates, replenishment serves to preserve the flow of stock across the value chain. However, firms run the danger of putting their operations in jeopardy without a robust replenishment plan.

Restocking storage shelves with fresh merchandise from vendors or sources of manufacture is referred to as refilling. It additionally has the potential to describe the transfer of goods or supplies from an archive to choosing shelves.

In simple terms, restocking short or unavailable popular goods is, putting it plainly, restocking. Replenishing is done to make sure a merchant has the proper amount of goods, in the correct place, at the appropriate moment in order to increase sales and cut costs.

A single individual or multiple teams may be assembled to manage inventory, according to the particular business structure. These groups typically include coordinators and/or warehouse directors who can be deemed responsible for making sure the business has adequate inventory to create supplies.

The groups can be classified into different specialties, with some of them concentrating on stock ordering processes as the organisation expands and changes; and others concentrating on the immediate. The latter group includes experts who dedicate time to keeping track of what is in stock.

Related Terms

- Trailing Stops

- Exchange Control

- Relevant Cost

- Dow Theory

- Hyperdeflation

- Hope Credit

- Futures contracts

- Human capital

- Subrogation

- Qualifying Annuity

- Strategic Alliance

- Probate Court

- Procurement

- Holding company

- Harmonic mean

- Trailing Stops

- Exchange Control

- Relevant Cost

- Dow Theory

- Hyperdeflation

- Hope Credit

- Futures contracts

- Human capital

- Subrogation

- Qualifying Annuity

- Strategic Alliance

- Probate Court

- Procurement

- Holding company

- Harmonic mean

- Income protection insurance

- Recession

- Savings Ratios

- Pump and dump

- Total Debt Servicing Ratio

- Debt to Asset Ratio

- Liquid Assets to Net Worth Ratio

- Liquidity Ratio

- Personal financial ratios

- T-bills

- Payroll deduction plan

- Operating expenses

- Demand elasticity

- Deferred compensation

- Conflict theory

- Acid-test ratio

- Withholding Tax

- Benchmark index

- Double Taxation Relief

- Debtor Risk

- Securitization

- Yield on Distribution

- Currency Swap

- Overcollateralization

- Efficient Frontier

- Listing Rules

- Green Shoe Options

- Accrued Interest

- Market Order

- Accrued Expenses

- Target Leverage Ratio

- Acceptance Credit

- Balloon Interest

- Abridged Prospectus

- Data Tagging

- Perpetuity

- Hybrid annuity

- Investor fallout

- Intermediated market

- Information-less trades

- Back Months

- Adjusted Futures Price

- Expected maturity date

- Excess spread

- Quantitative tightening

- Accreted Value

- Equity Clawback

- Soft Dollar Broker

- Stagnation

- Decoupling

- Holding period

- Regression analysis

- Wealth manager

- Financial plan

- Adequacy of coverage

- Actual market

- Credit risk

- Insurance

- Financial independence

- Annual report

- Financial management

- Ageing schedule

- Global indices

- Folio number

- Accrual basis

- Liquidity risk

- Quick Ratio

- Unearned Income

- Sustainability

- Value at Risk

- Vertical Financial Analysis

- Residual maturity

- Operating Margin

- Trust deed

- Leverage

- Profit and Loss Statement

- Junior Market

- Affinity fraud

- Base currency

- Working capital

- Individual Savings Account

- Redemption yield

- Net profit margin

- Fringe benefits

- Fiscal policy

- Escrow

- Externality

- Multi-level marketing

- Joint tenancy

- Liquidity coverage ratio

- Hurdle rate

- Kiddie tax

- Giffen Goods

- Keynesian economics

- EBITA

- Risk Tolerance

- Disbursement

- Bayes’ Theorem

- Amalgamation

- Adverse selection

- Contribution Margin

- Accounting Equation

- Value chain

- Gross Income

- Net present value

- Liability

- Leverage ratio

- Inventory turnover

- Gross margin

- Collateral

- Being Bearish

- Being Bullish

- Commodity

- Exchange rate

- Basis point

- Inception date

- Riskometer

- Trigger Option

- Zeta model

- Racketeering

- Market Indexes

- Short Selling

- Quartile rank

- Defeasance

- Cut-off-time

- Business-to-Consumer

- Bankruptcy

- Acquisition

- Turnover Ratio

- Indexation

- Fiduciary responsibility

- Benchmark

- Pegging

- Illiquidity

- Backwardation

- Backup Withholding

- Buyout

- Beneficial owner

- Contingent deferred sales charge

- Exchange privilege

- Asset allocation

- Maturity distribution

- Letter of Intent

- Emerging Markets

- Consensus Estimate

- Cash Settlement

- Cash Flow

- Capital Lease Obligations

- Book-to-Bill-Ratio

- Capital Gains or Losses

- Balance Sheet

- Capital Lease

Most Popular Terms

Other Terms

- Options expiry

- Adjusted distributed income

- International securities exchanges

- Settlement currency

- Federal funds rate

- Active Tranche

- Convertible Securities

- Synthetic ETF

- Physical ETF

- Initial Public Offering

- Buyback

- Secondary Sharing

- Bookrunner

- Notional amount

- Negative convexity

- Jumbo pools

- Inverse floater

- Forward Swap

- Underwriting risk

- Reinvestment risk

- Final Maturity Date

- Payment Date

- Secondary Market

- Margin Requirement

- Mark-to-market

- Pledged Asset

- Yield Pickup

- Subordinated Debt

- Treasury Stock Method

- Stochastic Oscillator

- Bullet Bonds

- Basket Trade

- Contrarian Strategy

- Notional Value

- Speculation

- Stub

- Trading Volume

- Going Long

- Pink sheet stocks

- Rand cost averaging

- Sustainable investment

- Stop-limit sell order

- Economic Bubble

- Ask Price

- Constant prepayment rate

- Covenants

- Stock symbol

- Companion tranche

- Synthetic replication

- Bourse

Know More about

Tools/Educational Resources

Markets Offered by POEMS

Read the Latest Market Journal

Navigating the vast world of unit trusts can be daunting. With nearly 2000 funds available...

Predicting Trend Reversals with Candlestick Patterns for Beginners

Candlestick patterns are used to predict the future direction of price movements as they contain...

In the diverse and complex world of investing, unit trusts stand out as a popular...

Back in Business: The Return of IPOs & Top Traded Counters in March 2024

Start trading on POEMS! Open a free account here! At a glance: Major indices continue...

Weekly Updates 15/4/24 – 19/4/24

This weekly update is designed to help you stay informed and relate economic and company...

From $50 to $100: Unveiling the Impact of Inflation

In recent years, inflation has become a hot topic, evoking strong emotions as the cost...

Japan’s Economic Resurgence: Unveiling the Tailwinds Behind Nikkei 225’s Record Leap

Source: eSignal, Intercontinental Exchange, Inc. In the heart of Japan’s economic landscape, the Nikkei 225...

Weekly Updates 8/4/24 – 12/4/24

This weekly update is designed to help you stay informed and relate economic and...